Aircraft Procedure - Introduction

Pilots

are highly trained professionals who fly airplanes and helicopters to carry out

a wide variety of tasks.

Except

on small aircraft, two pilots usually make up the cockpit crew. Generally, the

most experienced pilot, the captain,

is in command and supervises all other crew members. The pilot and copilot share

flying and other duties, such as communicating with Air Traffic Controllers and

monitoring the instruments. Some large aircraft have a third pilot—the flight engineer—who assists the other pilots by monitoring and

operating many of the instruments and systems, making minor in flight repairs,

and watching for other aircraft. (but nowadays this duty is performed by pair of

computers) New technology can perform many flight tasks, however, and

virtually all new aircraft now fly with only two pilots, who rely more heavily

on computerized controls. As older, less technologically sophisticated aircraft

continue to be retired from airline fleets, the number of flight engineer jobs

will decrease.

Before

departure, pilots plan their flights carefully. They thoroughly check their

aircraft to make sure that the engines, controls, instruments, and other systems

are functioning properly. They also make sure that baggage or cargo has been

loaded correctly. They confer with flight Dispatchers and aviation weather

forecasters to find out about weather conditions en route and at their

destination. Based on this information, they choose a route, altitude, and speed

that will provide the fastest, safest, and smoothest flight. When flying under

instrument flight rules—procedures governing the operation of the aircraft

when there is poor visibility—the pilot in command, or the airline dispatcher,

normally files an instrument flight plan with air traffic control so that the

flight can be coordinated with other air traffic.

Takeoff

and landing are the most difficult parts of the flight, and require close

coordination between the pilot and first officer. For example, as the plane

accelerates for takeoff, the pilot concentrates on the runway while the first

officer scans the instrument panel. To calculate the speed they must attain to

become airborne, pilots consider the altitude of the airport, outside

temperature, weight of the plane, and speed and direction of the wind. The

moment the plane reaches takeoff speed, the first officer informs the pilot, who

then pulls back on the controls to raise the nose of the plane.

Unless

the weather is bad, the actual flight is relatively easy. Airplane pilots, with

the assistance of autopilot and the flight management computer, steer the plane

along their planned route and are monitored by the air traffic control stations

they pass along the way. They regularly scan the instrument panel to check their

fuel supply, the condition of their engines, and the air-conditioning,

hydraulic, and other systems. Pilots may request a change in altitude or route

if circumstances dictate. For example, if the ride is rougher than expected,

they may ask air traffic control if pilots flying at other altitudes have

reported better conditions. If so, they may request an altitude change. This

procedure also may be used to find a stronger tailwind or a weaker headwind to

save fuel and increase speed.

Pilots

must rely completely on their instruments when visibility is poor. On the basis

of altimeter readings, they know how high above ground they are and whether they

can fly safely over mountains and other obstacles. Special navigation radios

give pilots precise information that, with the help of special maps, tells them

their exact position. Other very sophisticated equipment provides directions to

a point just above the end of a runway and enables pilots to land completely

“blind.” Here the air traffic engineers play major role to keep the ground equipment

to their absolute specification for "blind" landing. Once on the

ground, pilots must complete records on their flight for their organization and

the FAA. report.

Although flying does not involve much physical effort, the mental stress of being responsible for a safe flight, no matter what the weather, can be tiring. Pilots must be alert and quick to react if something goes wrong, particularly during takeoff and landing.

Simple lesson plan

to fly

Flight

Plans

Pilots wishing to fly under IFR rules must first file a

flight plan with Air Traffic Control, before departure. Calling the

Aeronautical Information Office can do this. The flight plan contains the

aircraft identification, or callsign, the type of aircraft, planned speed

(true airspeed, or speed across the ground without wind), requested route

of flight (from VORTAC to VORTAC), planned cruising altitude, and sometimes

other information such as color of aircraft, and number of people on board. We

will discuss all these later and for the time being have these in mind.

This flight plan information goes into the Air Traffic

Controllers and they prepare a strip of paper called a flight progress

strip. After that, controllers can review the proposed route of flight and

make changes as necessary to conform to local procedures and routings.

When the aircraft is ready to depart, the pilot calls either

the control tower and requests clearance. The controller checks the

flight strip, and clarifies the routing and any changes to the routing with the

pilot, so both pilot and Air Traffic Control know the exact route the pilot will

fly.

The controller also tells the pilot his flight plan code

number, and the pilot sets an instrument on his aircraft called a transponder

to transmit this code. This beacon code transmission is picked up by radar,

allowing the ATC computer to know exactly which aircraft it is, and which flight

plan it corresponds to.

Getting started

Imagine you

enter the cockpit of a parked A340 - everything is ready except that all systems

are shut down. APU (Auxiliary power unit) and engines are also switched off.

Now

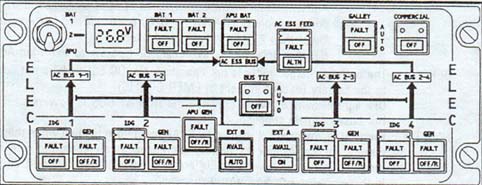

both batteries are switched on at the Overhead ELEC panel.

Overhead

ELEC (electrical) panel

The next

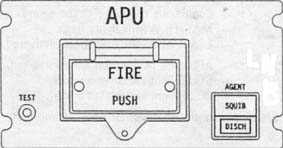

thing to do is to check the APU fire warning. To do this, the TEST button on the

APU fire panel is depressed and released when the fire light illuminates.

APU

fire warning

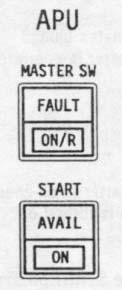

Now the APU

is switched on by pushing the MASTER switch on the APU panel.

APU

panel

When

the "FLAP OPEN" message appears on the ECAM (Electrical Contactor and Management Unit)

the APU start switch is depressed.

When the

AVAIL light illuminates, the APU bleed push button on the AIR panel is pushed to

supply the air conditioning and other systems with air.

Check

the all panels for white lights out and turn the three IR switches to NAV for

the alignment process.

Refer to

the following MCDU (Multifunction

Control Display Unit) programming

procedure.

STATUS PAGE (PS)

The

DATA BASE validity must be checked at first, as well as the navaids and

waypoints.

FLIGHT PLAN

Should be completed thoroughly. It

includes data like: Take off runway, SID with ALT/SPD data, expected take off

time, course, waypoints and the expected step climbs descents

SEC FLIGHT PLAN

Must be filled in when ever a

specific condition is likely to happen such as take off runway change,

alternative SID etc.

RAD NAV (Radio and Navigation)

Any required Navaids manually entered

using ident.

INIT

Winds,

expected ZFWCg (Zero

Fuel Weight Center of Gravity / ZFW (Zero Fuel Center

of Gravity),

Fuel planning: The FMGS (Flight Management Guidance System)

calculation the minimum required fuel this value must confirmed. After that, the

DATA page is selected and the preflight data is printed out using the ACARS

(Aircraft Communications Addressing and Reporting System). The

printed sheet must be kept as it gives the required fuel for each waypoint of

the Flight Plan.

PERF (Performance)

The derated climb and descents and

speeds are typed in - this is necessary.

Flight plan checked:

MCDU: FPLN page ND (Navigation

Display) in plan mode: range as required, with CSTR selected on EIS CTLE panel.

ALT/SPD checked, Distance to successive waypoint is provided. The overall

distance of the route is indicated in the 6th line of the MCDU

Now the

before Start Checklist (written on the table) can be completed. Before starting

the engines, turn the beacon light on and seat belts to on.

ATC communication

Now check

your departure time and you are ready for startup. Before that, contact the

control tower (Aerodrome) for clearance for startup and pushback the aircraft to

taxiway.

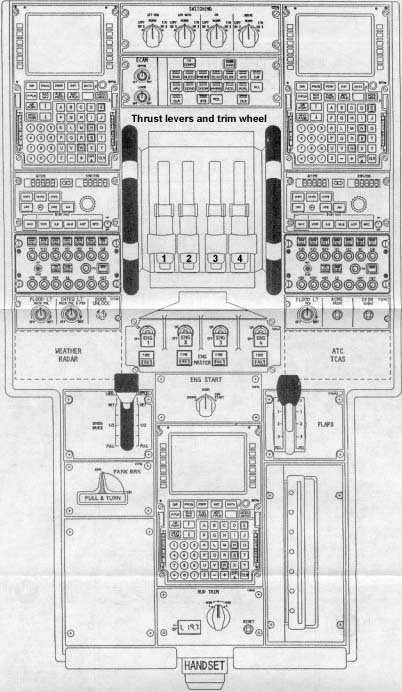

Engine Start up

The normal

engine start procedure is the AUTO START procedure. In this case the FADEC

prevents start malfunctions like hot start, stall etc. It recognizes all of

these and takes appropriate actions for instance reducing fuel flow, cranking

the engine, attempting new starts or cutting fuel flow. The air from the APU (APU

bleed) allows to start 2 engines simultaneously.

The engine

start up sequence is simple: 1 and 2 are started firstly to pressurize the green

and blue system which supply the parking brakes and hydraulic actuators. An

actuator is a little box that converts the electrical inputs to real rudder

movements. The Boeing B707 for instance doesn't have this system. Engine 1 and 2

first, followed by 3 and 4. Check thrust levers idle.

Engine Start

Then set IGN/START

to START - now an eye must be kept on the ECAM to check if APU bleed is stable.

ENG1 Master switch is set to ON followed by ENG 2 when N2 of Engine 1 has

reached 10%. Now monitor and check in the right order: Start valve open (now

high pressure bleed air (minimum 30psi) air is blown into the engine), N2 IGN A

or B, Fuel flow, EGT OIL PRESS ignition rising. FADEC (Full Authority Digital

Engine Control) closes the start valve when N2 reaches 50%, now monitor EGT and

ENG Vibration and the engine AVAIL which illuminates when the start sequence is

over. Now the same is repeated for ENG 3 and 4.

When all

engines are running stable set the IGN / START switch back to NORM which

automatically switches the Packs back ON. If, for any reasons, there is an

abnormal start DO NOT interrupt the FADEC protective and just follow the ECAM

instructions if they appear.

Another

procedure to start the engines is the MANUAL START, which is only used in

exceptional cases, like high altitude airports or subsequent low APU bleed

pressure or to CRANK the engine dry prior opening the fuel flow.

Overhead Panel

Taxi

When all

engines are running check both left and right side for any obstacles let the

tore bar to pull the aircraft on to the correct path from the apron. Again,

contact the tower and get the clearance to enter the taxiwayan most of the time

you will be asked to enter the taxiway either to runway 22 or 04 and hold short

of runway. Now, smoothly move the thrust levers forward - only a few centimeters

as otherwise you would blow everything away that is standing behind you and

therefore you do not exceed N1 40% during taxi.

The APU

bleed should be turned off to avoid ingestion of exhaust gases by the

passengers.

On straight

taxiway and shallow turns the pedals are used to steer the aircraft but the hand

is kept on the steering tiller is used in sharp turns. Be careful with that - it

is very sensitive so move this wheel very slowly. Also, when on the ground do

not start turns too early. Remember that the nose gear on the A340 is far back

(4 meters), this means that the cockpit has to be over the grass in an

intersection. If you turn too early the main gear can end up in the grass so

make sure to over steer significantly.

Slowly move

the thrust lever 1 (left one) slightly forward to make a right turn and use the

right lever for number 4 engine slightly forward to make a left turn. It is not

recommended to use differential braking to avoid gear stress. The speed

shouldn't exceed 10 knots in turns also if brake temperature exceeds 150°

degrees the brake fans (not installed in all aircraft) must be switched on.

Remember to taxi slowly at about 10-12 knots. You usually do not use thrust

reverser during taxi and it is used on old 737-200s or MD80s but not on the

newer aircrafts.

Extend the

flaps to 1 + F the lever is located on the center panel and you simple pull the

handle up and move it down one step. Make sure the stabilizer trim is in the

green range and the rudder trim at zero.

Take

off

Here you

have come most critical point of your adventure. Contact the tower again and

request for take off. You will be cleared to enter the runway and takeoff.

When turning

onto the runway, switch on the strobes and landing lights and align the aircraft

on the center line and select Auto Brake MAX on the main instrument panel (below

the gear indicator)In case of an engine failure the aircraft stops automatically

when the thrust levers are moved to IDLE. Then push the CONFIG test on the ECAM

so as to insure that the ECAM take off check list items are all green.

If

everything is set the thrust levers are moved slowly to 50% N1 and when all

engines are running stable at 50% move the levers the stops (TOGA). A yellow

arrow appears on the PFD indicating the acceleration. Now full concentration is

needed to monitor speed, engine gauge and the aircraft on the centerline.

At 90 knots, the rudder has to be used to keep the aircraft aligned with the centerline as at 100 knots the nose gear steering disconnects from the nose gear.

This is actually the most tricky part of the take off run and in case of an engine failure it is difficult to keep the aircraft aligned with the center line as the airspeed is still to low for an effective rudder and the nose gear steering is disconnected.

This

is why much attention has to be paid on the engine gauges at this stage to react

as early as possible. At 140 knots smoothly move the side stick backwards to

gain a pitch attitude of 8° to avoid tail strike and then to 12-15° (depending

on weigh). The Autopilot is available 5 seconds after take off.

CLB/CRZ/DES(Climb/

Cruise/ Descend)

When a

stable positive rate of climb is established the gear is selected up and thrust

reduced to CLB at 1500feet. The flaps are retracted at 200kts but as this only a

traffic pattern they are set to 1. In case of a traffic pattern, usually you

maintain 1500 feet above ground. You can use the autopilot for the traffic

pattern. Just press AP1 and Pull + rotate the altitude knob to 1500 and then

pull it. Now select your desired heading - simply add 180° to your current

heading to make a 180-degree turn to fly the downwind leg of the traffic pattern.

From now on, until landing, the aircraft is under observation of the Air Traffic

Control system. After departure, ATC issues altitudes, speeds, headings, and

sometimes re-routes as necessary, and assumes responsibility for separating the

aircraft from all known traffic.

Landing

Put the FLAP

lever to 2 and select 160 knots airspeed. Now put the gear lever to down and the

FLAP lever to 3. Select 140 knots speed. Before turning on final extend the

flaps to FULL and arm the spoilers and push the Autobrake switch to Medium - you

do not use Autobrake max during landing. Now the aircraft should be aligned with

the runway centerline with the localizer display indicator and have an airspeed

of 140 knots with the gear down and flaps set to FULL and a rate of descent of

700-800 feet per minute and a pitch angle of 4-5°(but the actual landing angle

should be 3°). These parameters need to be monitored constantly - never fix

your eyes on one parameter always keep all parameters in view.

The PAPI

will help you to establish the correct glide path. The PAPI (Precision Approach

Position Indicator) consists of 4 lights which can illuminate red or white. If

you see 2 red and 2 white lights than the glide path is correct - if 3 reds and

1 white is seen than slowly add power and smoothly pull the stick backwards to

reduce the ROD. But most of you will know how this works either from real life

or from the flight simulator.

When passing

500 feet a voice message is heard indicating 500ft so monitoring altitude above

ground does not have high priority.

It is very

important to keep the speed at 140 knots and if it is below 140kts then in most

cases this will result in a hard landing if the speed is to high the aircraft

will climb during the landing flare.

Switch the

Autopilot off by pressing the red side stick button twice and press one of the

red buttons twice on the thrust levers to disengage the outthrust system. A

short aural warning will be hared. Continue descent at 700 feet per minute until

reaching 30 feet. Now reduce rate of descent to half and count slowly 1, 2, 3

while retarding the thrust lever to idle when the retard call is heard. Avoid

push the stick forward if not absolutely necessary and

this will increase the rate of descent and result in a hard landing. To

make it correct always give very little side stick inputs and monitor what

happens and if descending to fast pull the stick back again but always small

inputs and monitor speed. Also remember a nice approach is almost a nice landing

so if you monitored all parameters well a soft landing is not guaranteed.

When the

forward boogie touches the ground move the thrust reverser levers upwards and

the spoilers will be extend automatically. Now the landing is not over at all

and the nose gear has to be landed as well and if you keep it up to long it will

just fall down and this is not very comfortable therefore, slowly move the side

stick forward and give a little input and just see what happens.

Shut

down

Take the

next intersection and taxi to the apron. Push the spoiler lever down, retract

the flaps to zero, switch off the strobes and landings lights and reduce speed

to 10-12 knots. Make sure the APU is on when parking position is reached. Set

parking brake and move the Engine Master switches to OFF one after another. Turn

of the beacon light and seat belts.

After

the aircraft lands, the flight plan is closed, and the pilot turns off

his transponder.

The technical terms in the above

passage is expected to discuss in great detail with the help of a Airbus cockpit

instrument in the future. Therefore, please

bare with me keep on visiting the site for latest updates.

![]()